Pressure-Treated Wood vs. Composite Decking

14 March 20255 Common Myths About Composite Decking Debunked

27 January 2026

Circular Economy: How Ecoplast Transforms Waste into Premium Decking

Introduction: Redefining "Waste"

In a traditional linear economy, products are made, used, and then discarded. At Ecoplast, we operate differently. We have embraced the Circular Economy—a regenerative model where "waste" does not exist. By transforming post-consumer and industrial plastic into premium architectural decking, we are closing the loop on pollution and opening the door to sustainable luxury.

Sustainability isn't just a buzzword for us; it is the foundation of every board we manufacture.

Waste Recovery

We divert local HDPE plastic waste from landfills, giving it a second life as a durable resource.

Bio-Based Synergy

We integrate carbon-neutral wood fibers, creating a balanced and renewable material matrix.

Eco-Manufacturing

Our closed-loop process ensures that 100% of production scraps are recycled back into new boards.

Infinite Durability

A 25+ year lifespan reduces the need for replacement, minimizing long-term environmental impact.

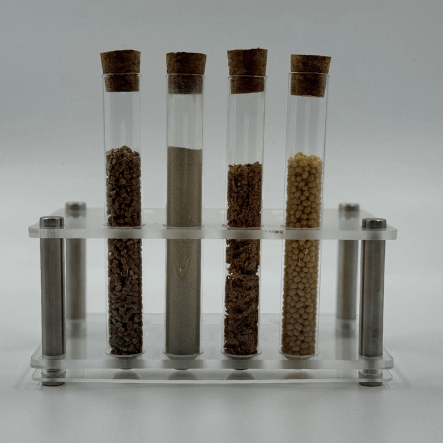

1. Plastic Transformation: From Ocean-Bound to Deck-Bound

High-Density Polyethylene (HDPE) is one of the most common plastics found in landfills. Ecoplast harvests this local waste and subjects it to an advanced cleansing and pelletizing process. This recycled HDPE becomes the structural backbone of our boards. Instead of polluting our oceans for five hundred years, this plastic is locked into a high-performance product with a certified structural strength of 34.4 MPa.

2. The Carbon-Neutral Advantage of Wood Fiber

While 100% plastic decking exists, it lacks the thermal stability and carbon benefits of wood. We combine our recycled HDPE with natural wood fibers—a renewable resource that captures carbon dioxide during its growth. This creates a carbon-neutral synergy. Our non-capped boards allow these natural fibers to breathe, providing a matte finish that looks like real timber because it contains real timber, without contributing to deforestation.

3. A Zero-Waste Production Facility

Sustainability isn't just about what we make; it’s about how we make it. Our Canadian manufacturing facility operates on a Closed-Loop System. Any board that doesn't meet our rigorous quality standards or any scrap generated during the cutting process is immediately reground and reintroduced into the production cycle. In an Ecoplast facility, nothing is wasted.

4. Building for the Future: LEED and ESG Goals

For professional developers and architects, Ecoplast is more than a supplier—we are a strategic partner for achieving Environmental, Social, and Governance (ESG) targets. Our products contribute directly to LEED certification points by utilizing 100% recycled content and eliminating the need for toxic stains and sealants throughout the deck's lifecycle. By choosing Ecoplast, you are opting for an infrastructure solution that meets the highest environmental standards in North America.

Build with Purpose

Ready to integrate true sustainability into your next project? Request our Technical Data Sheet and Environmental Impact Report today.