ECOPLAST

ECOPLAST will be the name of the very first wood-plastic composite (WPC) manufacturing plant in Quebec, which will be established on the South Shore of Montreal.

Obsolescence

The environment

Our planet, our ecosystems, and consequently our quality of life are threatened, which is why it is imperative to make more responsible choices.

Globalization

In order to remain competitive and viable, companies must turn to international manufacturers to reduce their production costs.

Providing a sustainable and eco-friendly alternative

Upcycling wood and plastic waste

Developing a local market, and doing so at a competitive price

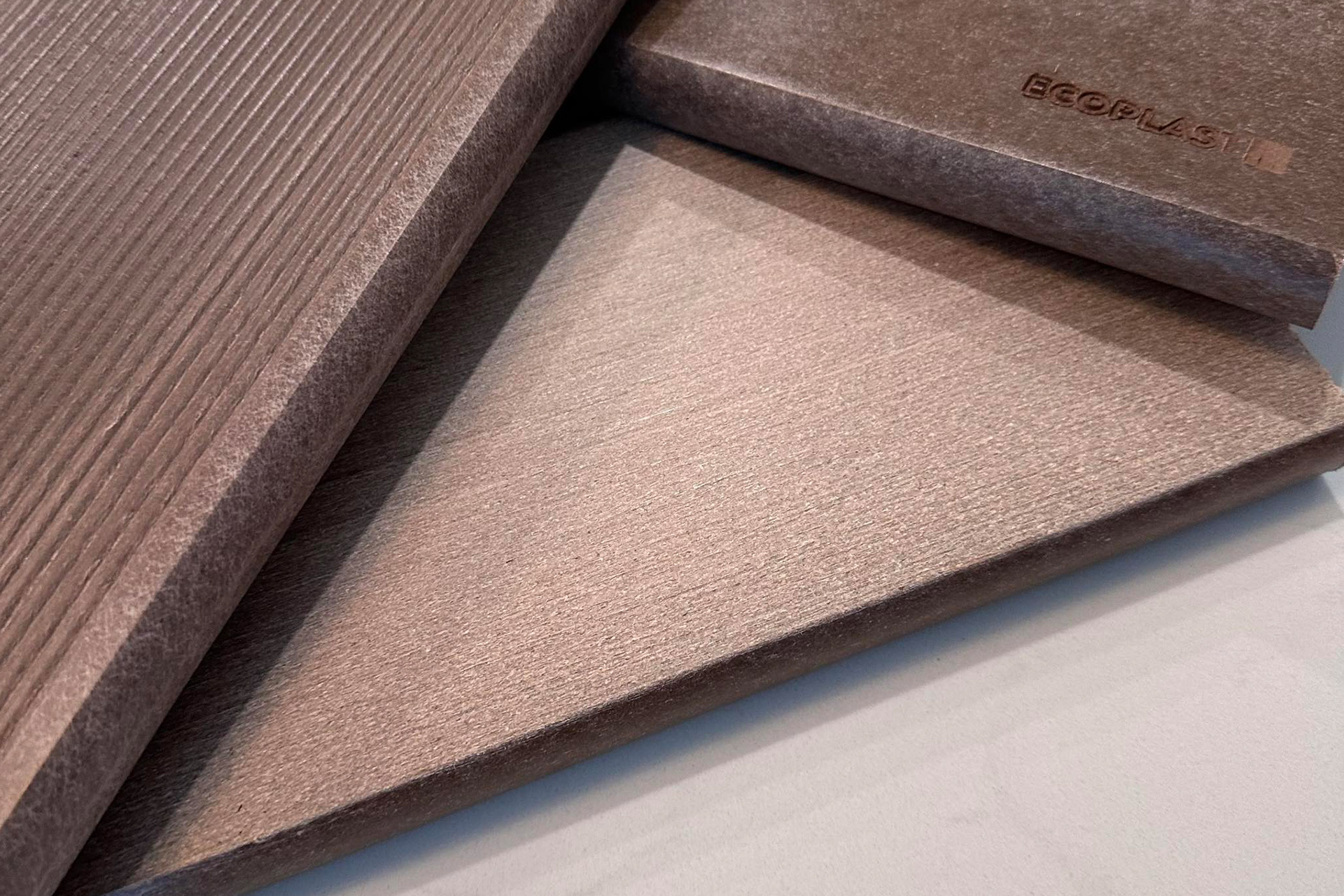

PRODUCTS

WPC in finished products

Offered in plank form, this product is ideal for outdoor installations due to its durability and low maintenance requirements. Our team of experts can tailor the manufacturing process to meet your specific needs. Finished WPC Customized WPC Various formats are also available and beneficial for many non-structural projects, thanks to the technical properties of this product

Customized WPC

Our team of experts is able to adapt the manufacturing process to meet your specific needs.

ECOPLAST

Value-added

100% recycled

Our products are entirely made from wood and plastic waste.

Durable

The numerous technical properties of WPC make it a material of choice for various uses.

Local

Contribute to the solution by purchasing a local and environmentally friendly product.

ECOPLAST

About us

Écoplast specializes in recycling plastic with wood residues to create a composite used in various outdoor products. By favoring a material with over 50% wood, greenhouse gas emissions are significantly reduced compared to a similar product made entirely of plastic. Moreover, we can tailor our product to meet your specific needs through recipe modifications.

ECOPLAST

Target markets

The composite materials market is expected to reach an estimated $40.2 billion in 2024 and grow at a rapid pace. The building and construction segment dominated the composite sales market, accounting for over 71% of global revenue share in 2021. In the automotive industry, the use of recyclable parts made from wood-plastic composites is expected to enhance mechanical strength, acoustic performance, reduce material weight and fuel consumption, lower manufacturing costs, improve passenger safety and sealing performance, thereby boosting demand for wood-plastic composites. Increasing demand for wood-plastic composites in consumer goods manufacturing, including toys and display items, is expected to drive market growth in the coming years. Annual growth of over 10% is anticipated over the next 5 to 6 years. As WPC capacity expands, new products will be developed to meet market needs.

Construction

Automobile

Food